TekSpan et Henry Ford - Amener le travail aux travailleurs

En 2010, j'ai visité l'usine Ford de Rouge River à Dearborn, dans le Michigan, où j'ai observé une chaîne de production de camions qui créait un F-150, du châssis nu à l'article fini, en l'espace de quelques minutes. Si vous aimez regarder des machines de précision fonctionner sans interruption, je vous recommande de vous rendre dans cette usine : c'est vraiment impressionnant à observer.

Créer quelque chose comme un camion 4×4 en moins de temps qu'il ne m'en faut pour écrire un billet de blog est un signe de ce que les processus de fabrication modernes peuvent accomplir, même avec ma vitesse de frappe de 3 mots par minute. Et c'est en grande partie grâce à la vision du grand Henry Ford que cela a été possible.

La vision de Ford dans les premières années de la décennie 20th siècle a révolutionné non seulement la fabrication, mais aussi l'industrie automobile naissante dans son ensemble. Au lieu de la pratique courante consistant à déplacer les techniciens et les équipes d'assemblage dans l'usine au cours des phases de construction, Ford a compris les nombreux avantages qu'il y avait à inverser ce modèle et à déplacer le véhicule dans l'usine, tout au long des différentes étapes de l'assemblage.

Cela signifie que les travailleurs restent dans la même zone de travail, effectuant exactement le même processus d'assemblage à chaque fois, gardant les outils et les matériaux au même endroit et permettant aux équipes d'assemblage d'affiner continuellement leurs compétences en matière d'assemblage véhicule après véhicule. Les personnes restaient au même poste de travail au lieu de se déplacer dans l'usine, ce qui leur permettait de se concentrer sur leur domaine d'expertise sans être distraites par les déplacements entre les zones de travail. C'est ainsi que le concept consistant à amener le travail aux travailleurs plutôt que les travailleurs au travail a été introduit dans l'industrie automobile.

Au départ, un système de convoyeur à corde était utilisé, mais au fur et à mesure que Ford développait cette chaîne de production - et que, ce faisant, l'efficacité et les bénéfices de la Ford Motor Company augmentaient - il a introduit un système de convoyeur à chaîne. Le système que j'ai vu à Dearborn en 2010 était un tapis roulant au niveau du sol qui propulsait progressivement le véhicule en développement entre deux lignes de démarcation jaunes ; chaque équipe d'assemblage restait à l'intérieur de ses propres lignes jaunes et, bien sûr, plus la phase d'assemblage est longue, plus les lignes sont éloignées les unes des autres - le convoyeur continue de rouler sans relâche.

Mais chez TekSpan, nous ne fabriquons pas de véhicules. Nous n'avons pas non plus de chaîne de fabrication, alors pourquoi prendre la peine de vous dire cela ?

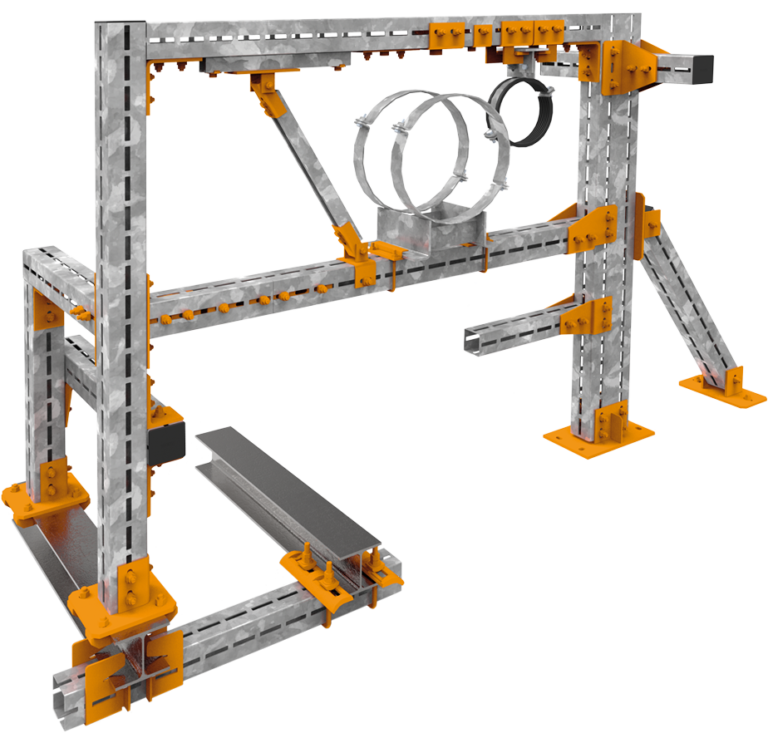

Parce qu'il existe un parallèle évident entre le processus de fabrication d'Henry Ford et les charpentes métalliques modulaires. Nous vendons d'ailleurs des charpentes métalliques modulaires.

Dans le monde de la construction, il est courant de construire des cadres de soutien en acier hors site et de les installer à l'aide d'une grue. Outre les installations de fabrication hors site, ce processus nécessite des transports et des grues pour acheminer la charpente de l'atelier au chantier, et peut nécessiter des ponts roulants, des fermetures de routes et des déplacements de camions articulés. Je ne dis pas que c'est une erreur, et dans certains cas, c'est même la seule façon de procéder, mais de nombreux cadres n'ont pas besoin d'être construits et déplacés de cette façon.

Au lieu de cela, si nous devions adopter la vision du progrès de Henry Ford, considérons les avantages qu'il y a à amener le travail aux travailleurs. Un petit camion livre sur le site des profils de 6 m de TekSpan qui peuvent être déplacés à la main jusqu'à des sous-sols ou des salles d'usine autrement inaccessibles, ainsi que des composants de joints encaissables et des boulons. Rien de plus technique qu'une meuleuse sans fil (pour effectuer les coupes nécessaires aux longueurs de 6 m) et une clé dynamométrique (pour serrer les boulons T-Lock à 120 Nm), TekSpan peut être érigé plus rapidement et plus efficacement que n'importe quel cadre en acier soudé. Pas de kit de soudage à trimballer, pas de meulage et de ressoudage en cas d'erreurs, de mesures erronées ou de variations, et pas de retard dans la finition par pulvérisation, grâce à la finition HDG. Et bien sûr, si vous coupez les longueurs avant la livraison du chantier, vous n'aurez pas besoin de permis de travail à chaud sur le chantier.

Tout comme la vision d'Henry Ford à l'époque, il faut un certain temps pour que des améliorations telles que les charpentes métalliques modulaires passent à travers les différentes couches du processus au sein de l'industrie - mais une fois qu'un entrepreneur a prouvé les avantages et la valeur de TekSpan, il ne revient pas en arrière.

Et pour paraphraser l'une des célèbres expressions d'Henry Ford, "Vous pouvez l'avoir dans toutes les couleurs que vous voulez, à condition qu'il soit galvanisé à chaud".